|

|

|

|

|

|

Ultrasonic Cleaning for Ceramic Anilox Rolls |

|

|

By Hu |

|

|

|

|

|

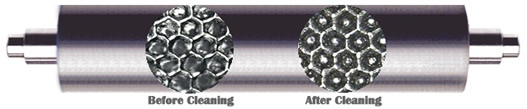

Nowadays, ceramic anilox rolls with properties of high hardness and long service life, are more and more applied for high-performance printing requirement especially in flexible printing industy. During the normal use, cell volume of rollers is gradually reduced by clogging and seriously impact on printing quality. That means anilox rollers need to be cleaned thoroughly. Ultrasonic cleaing method is known as the most successful mehtod for removing dried ink,

coating components and adhesives from the cells of anilox rolls depending on its excellent cleaning result.

|

|

Preparation for cleaning ceramic anilox rolls

1) Choose the optimal frequency for cleaning ceramic rollers

The ultrasonic frequency has an opposite effect on the power intensity, the lower the frequency, the stronger the cavitation effect. For instance, the higher power of the 20kHz system can clean the cells of anilox rollers more effectively, even so, meanwhile the powerful energy may damage cell walls. Obviously, under a higher frequency, it will take a long time to clean a roller, and the gentler cleaning process will not cause the damage to anilox surface. Generally, a minimum frequency of 40 kHz can guarantee enough energy intensity to remove the dirts in the cells without any damage. However, this frequency is only for reference, the optimal frequency should be decided according to the specific properties of the anilox rollers i.e. LPI.

2) Determine the proper time for cleaning ceramic rollers

Today's ultrasonic cleaning systems provide a much more gentle energy on ceramic anilox rolls. However, long-time cleaning process will still cause adverse

effects on cell walls. By time control system, we can limit the exposure time and minimize damage to a variety of anilox cells. Generally, higher line screen

surface require shorter cleaning times to avoid damage, the safe cleaning periods are recommended for reference as follows:

| Line Screen |

Below 320 |

350 to 400 |

430 to 650 |

650 to 1000 |

| Cleaning Periods |

20 min |

15 min |

10 min |

Below 3 min |

3) Select the appropriate cleaning solution for ceramic rollers

The suitable cleaning solution is significant to efficient cleaning on rollers. The improper use of solution will weak the cleaning effect and even cause the

damage. The desired cleaning solution even can make cleaning cycle as quickly as possible while requiring minimum ultrasonic energy, so that we should decide

the optimal cleaning detergent according to the different properties of ink or other choked materials.

4) Confirm the ceramic rollers without any cracks

Generally, the ceramic anilox rollers with high mass density have no adverse effect under the action of ultrasound. However, if there are any cracks in the

ceramic rolls, vibrating in resonance with ultrasonic wave will make them extent further, and the cleaning solution can penetrate directly inside their

substructure and cause corrosion. So that carefully check before cleaning tast is necessary.

The cleaning procedure of ceramic anilox rolls

1) Presoaking process

Considering the property of water-based ink, the pre-soaking method is essential to soft and loose inks, resins and other dirts from the cell walls in

specific cleaning solution. The temperature of cleaning solution are commonly maintained between 40℃ and 60℃. because we must use as much presoak and as

little ultrasonics as possible for the safe cleaning on rolls, the presoaking in the solution takes approx. 80% to 90% of time in the total cleaning process.

Based on this, it's possible to reduce the level of ultrasound energy and short the cleaning time in the next step, on the other hand, the ceramic rolls with

higher line screen even can be cleaned successfully.

2) Ultrasonic cleaning process

|

|

The ultrasonic cleaning equipment can be designed as total or partial immersion for anilox rolls in cleaning solution. Anyway, the ceramic rolls shoude be continuously rotated to ensure that every areas can be cleaned thoroughly. Through the ultrasonic cleannig cycle, plenty of cavitation bubbles implode on the surface of roll to release energy which are strong enough to remove the contaminants from anilox cells. Even so, the balance of various factors such as cleaning time and power instensity mentioned earlier in this article is important to achieve the best cleaning effect while protecting the ceramic anilox rolls. |

3) Rising and ending work

The final step is to rinse off the anilox rolls with clear water until there are no residual cleaning chemical on the surface, and then wipe rolls clean with

a soft cloth and keep them in a dry place for use next time.

|

|

« Back |

|

↑ Top |

|

|

|

|

Downloads

Downloads Sitemap

Sitemap Downloads

Downloads Sitemap

Sitemap